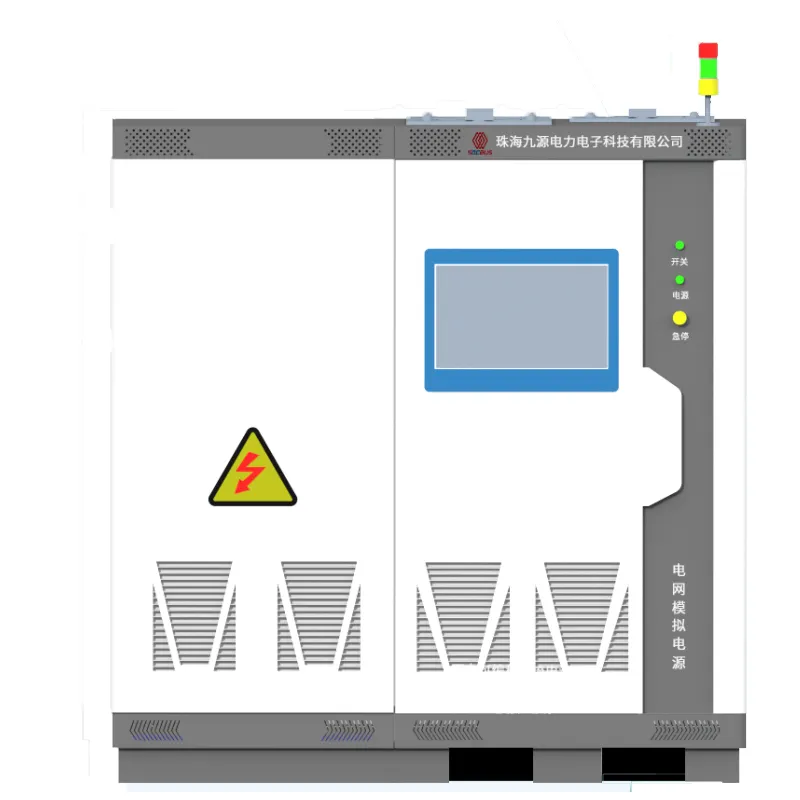

For engineers designing and validating electronic components and systems, performance testing is the critical gatekeeper of quality and reliability. While a programmable dc power supply 1000w or its AC counterpart serves as the essential stimulus, the true intelligence of a modern test bench lies in the system that measures, controls, and interprets the data. This article explores how to construct a high-performance test system, focusing on the critical role of data acquisition and robust communication, rather than just the power source itself. At Zhuhai Jiuyuan, we specialize in providing the sophisticated measurement and control backbone that transforms a simple power test into a comprehensive validation solution.

The Core Architecture of a Modern Test System

A state-of-the-art performance test setup is more than just a power supply. It is an integrated ecosystem where the Device Under Test (DUT) is subjected to precise power inputs, while its response is meticulously measured. The system typically comprises a programmable AC/DC power source (like a 1000W unit), a suite of sensors and data acquisition (DAQ) modules, and a master controller. The key to seamless operation is the communication network that binds them all, utilizing industrial-grade protocols like CAN bus, Daisy Chain, RS485, RS232, and Modbus for reliable, noise-immune data transfer and command execution over long distances within a lab or production environment.

Validating Consumer Electronics and IoT Devices

The mass market for consumer electronics, from smart home gadgets to wearable tech, demands rigorous performance validation. A test system can use a programmable AC power supply to simulate typical wall adapter output or various brown-out conditions. Simultaneously, high-precision DAQ modules monitor the DUT's current draw, power efficiency, and thermal behavior. Using a daisy chain configuration, multiple DAQ modules can stream data back to a host computer through a single connection, simplifying wiring and allowing for synchronized measurement of multiple parameters like voltage, current, and temperature during stability and battery life tests.

Precision Characterization of Low-Power Components

In the R&D phase for components like advanced sensors, communication modules, or medical implants, understanding micro-level power consumption is vital. Here, a system that integrates a clean power stimulus with nanosecond-level measurement accuracy is indispensable. The test system can employ the power supply to provide stable or dynamically changing voltages while the DAQ system captures inrush currents and sleep-mode leakage with extreme precision. RS485 or Modbus networks are ideal for this application, ensuring accurate data collection from measurement instruments without interference, which is crucial for validating the ultra-low-power claims of a new chip or circuit.

Automated End-of-Line Functional Verification

In a manufacturing setting, speed and repeatability are paramount. An automated test system can be built where a controller, programmed with test sequences, commands the power supply to apply specific voltages to each DUT. The system then verifies functionality by reading pass/fail signals and key performance parameters through its acquisition modules. The use of the CAN bus is highly advantageous here due to its robustness and multi-master capability, allowing multiple test stations to communicate efficiently on the same network, significantly streamlining the production test workflow.

Conclusion: The Intelligence is in the System

While a high-quality programmable dc power supply 1000w is a vital component for providing the test stimulus, it is the sophisticated data acquisition and control system that unlocks its full potential. By building a test architecture with robust communication via CAN, Daisy Chain, or Modbus, engineers can create automated, precise, and scalable test solutions. This approach moves beyond simple power application to comprehensive performance analysis, ensuring product excellence from the lab bench to the end-user.