Introduction

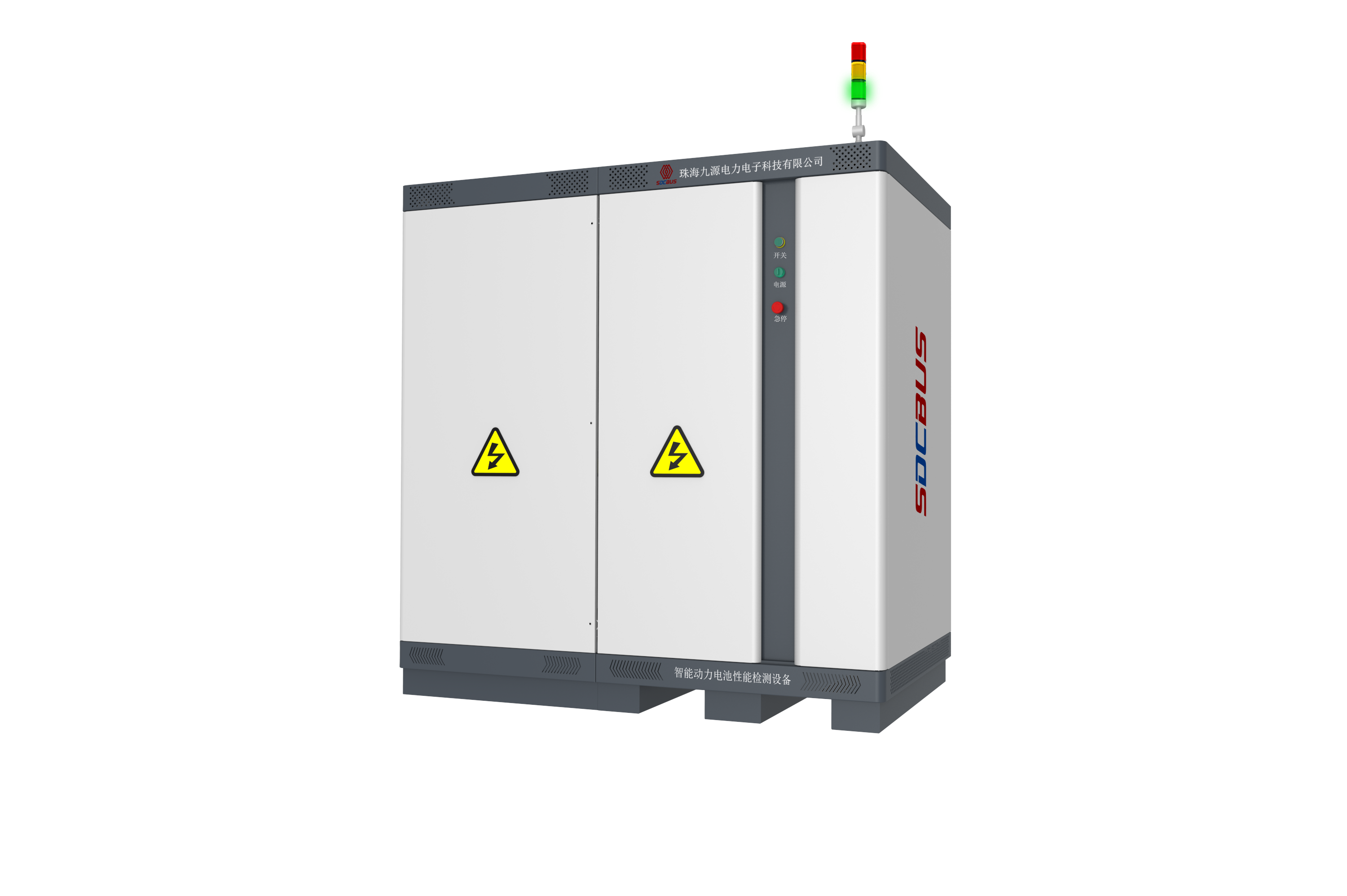

Accurately determining a battery's capacitance, or its actual capacity, is fundamental to assessing its State of Health (SOH) and performance. For manufacturers and R&D departments working with battery modules and packs, this requires a precise, reliable, and efficient testing solution. This article outlines the professional steps for conducting a comprehensive capacitance test battery procedure, demonstrating how advanced systems like Zhuhai Jiuyuan's SDCBUS Series Power Battery Test Systems streamline this critical process.

Understanding the Goal of a Battery Capacitance Test

The primary goal of a capacitance test battery is to measure the total amount of charge a battery can store and deliver, compared to its rated specification. This is typically done through a controlled charge-discharge-charge cycle. The result, measured in Ampere-hours (Ah), directly indicates the battery's degradation and remaining useful life. For high-stakes applications, the precision and repeatability of this test are paramount.

Leveraging an Automated Test System

The cornerstone of a modern test workflow is an automated, high-precision system. The SDCBUS Series provides an integrated solution that replaces manual and less accurate methods. Its core advantage in a capacitance test battery scenario is its dual functionality as both a precision charger and an electronic load with energy recovery, all managed by automated software. This eliminates the need for separate, inefficient equipment.

Step 1: System Configuration and Channel Setup

Before testing, the system must be configured. For the SDCBUS system, this involves:

- Physical Connection: Connecting the battery module or pack to an available channel on the test system. The system's support for multi-channel configurations allows for parallel testing of multiple units, drastically improving throughput.

- Software Setup: Using the integrated software to create a test plan. This is where you define the specific capacitance test battery parameters.

Step 2: Defining the Critical Test Parameters

The accuracy of the test hinges on correct parameter input. In the software, you will configure:

- Battery Specifications: Nominal voltage and the original rated capacity (e.g., 100Ah).

- Test Cycle: Setting up a standard charge, rest, discharge, and rest profile.

- Voltage Limits: Defining the upper charge cutoff voltage and the lower discharge cutoff voltage to protect the battery.

- Current Rates: Setting the constant current (CC) for charge and discharge phases.

Step 3: Executing the Test with Energy Recovery

Initiating the test sequence starts the automated cycle. This is where the SDCBUS system's key technological advantages come into play:

- High-Precision Measurement: The system captures voltage and current with exceptional accuracy (e.g., ±0.05% reading), ensuring the resulting capacity data is reliable.

- Energy Regeneration: During the discharge phase, instead of wasting energy as heat, the system converts it back to AC power and feeds it into the building's grid. This energy regeneration function, with efficiency over 96%, significantly reduces the operational cost and cooling requirements of testing, making high-volume capacitance test battery cycles sustainable.

Step 4: Data Analysis and Health Assessment

Upon completion, the system generates a detailed report. The key metric is the measured discharge capacity. By comparing this to the rated capacity, the State of Health (SOH) is calculated: (Measured Capacity / Rated Capacity) x 100%. Advanced systems also provide data curves for deeper analysis of voltage and current behavior throughout the cycle.

Conclusion: The Value of an Integrated Solution

Performing a capacitance test battery is more than just a procedure; it's a critical component of quality assurance. By utilizing an integrated system like the SDCBUS Series, you achieve not only high-precision results but also benefit from energy savings, automation, and the robustness required for a high-volume test environment. This approach ensures you gain a true and reliable understanding of your battery products' performance.