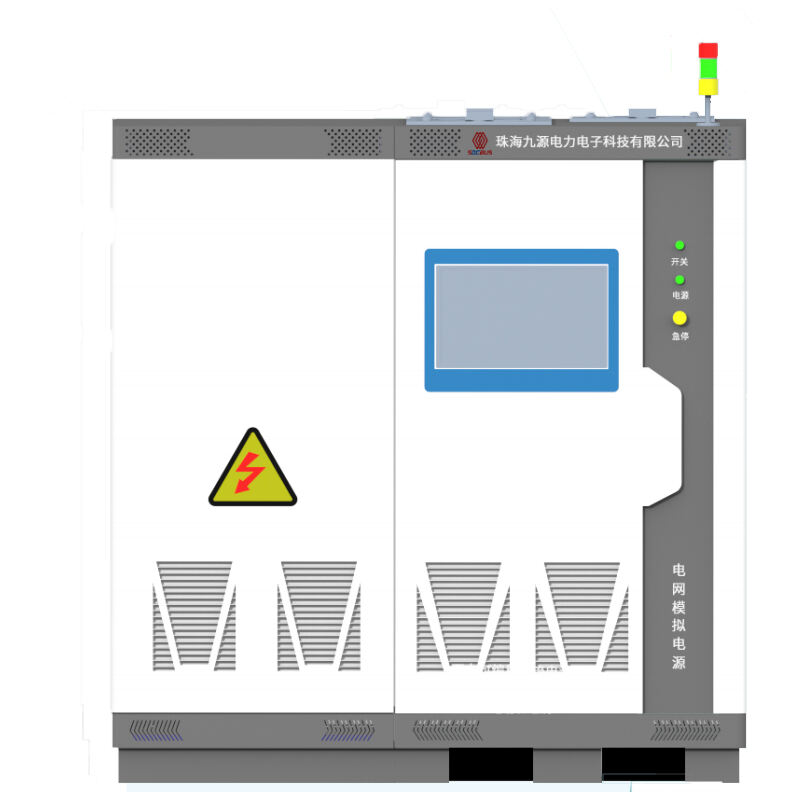

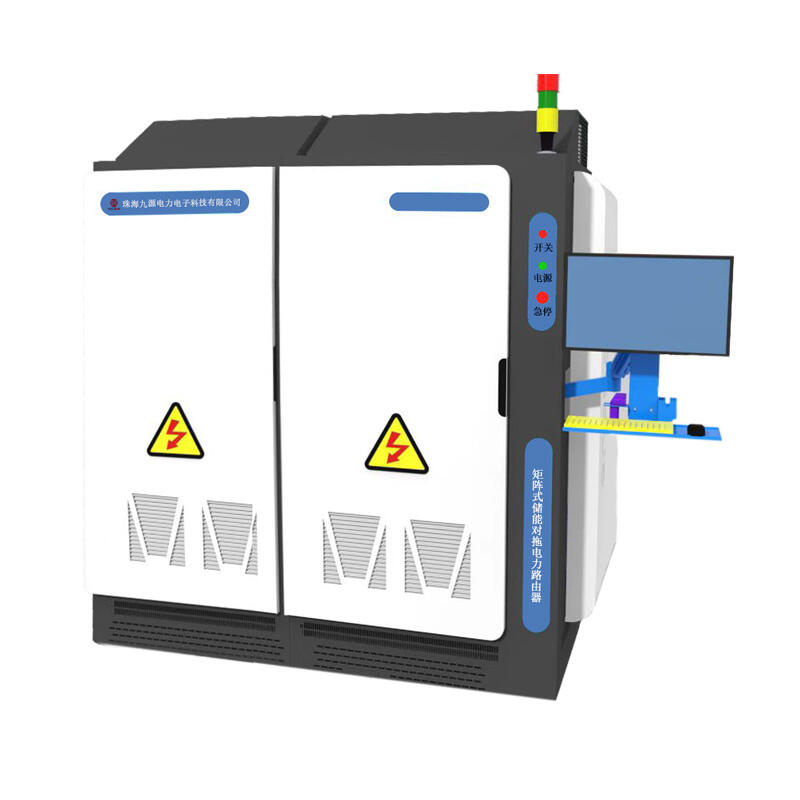

Lithium Battery Electrical Performance Test System (2400V)

The SDCBUS Series is a high-precision AC/DC power processing system featuring bidirectional power flow for unidirectional and bidirectional load testing.By replacing traditional resistive loads,it minimizes energy loss while enabling grid-connected power control.By eliminating resistive load power consumptio, the system significantly reduces energy loss.

- Dimension (L x W x H mm): 4280 x 1200 x 1900

- Weight(kg):5400

Application

![]()

- Overview

- Recommended Products

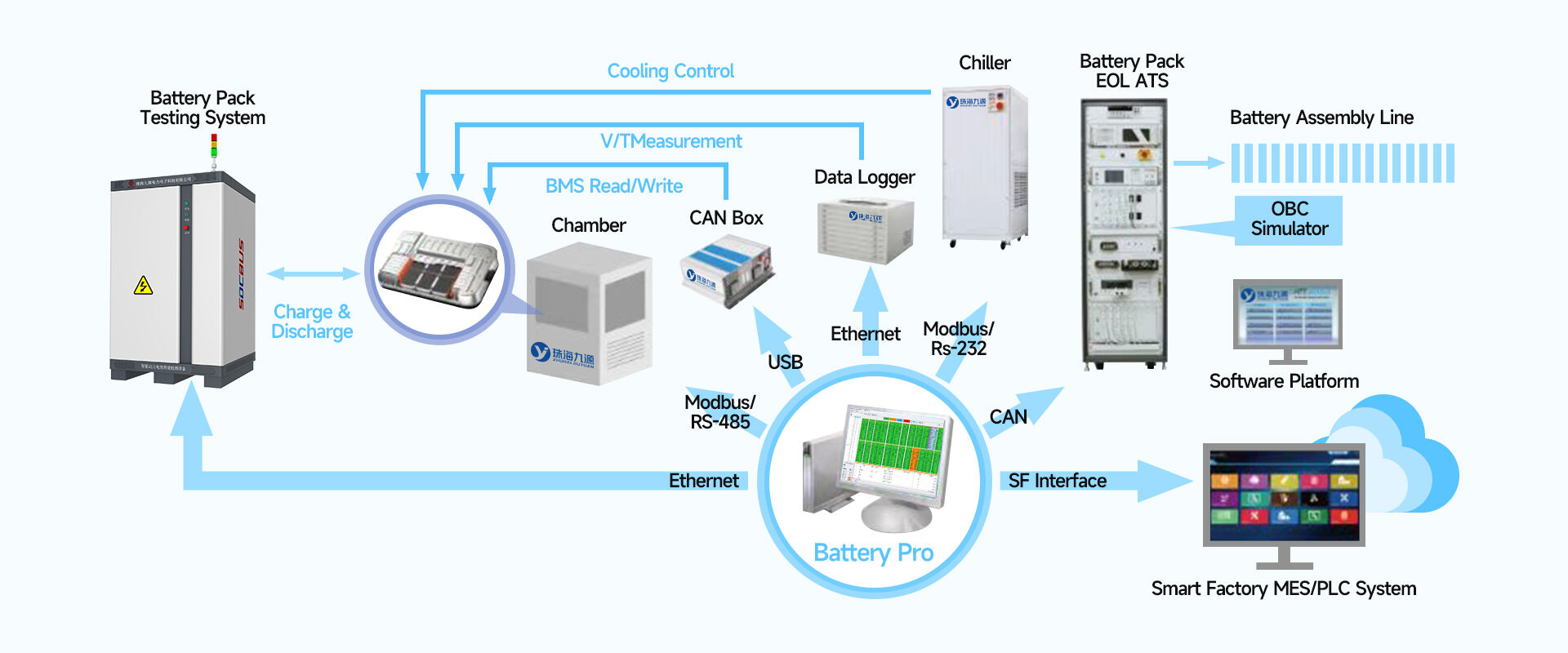

Our SDCBUS Series provides an end-to-end solution for battery pack testing, from cell assembly to final quality assurance. By integrating test equipment, cooling control, communication interfaces, and software, it enables:

☑ Reliable performance evaluation

☑ Real-time monitoring and logging

☑ Automated data analysis

☑ Smart factory integration

This ensures battery packs meet safety, reliability, and efficiency standards before use in EVs or energy storage systems.

Product Features

1. Patented Topology: Optimal energy-saving control.

2. Core Converter Module Cable-Free Design: Stable, reliable, worry-free operation.

3. Phase-Sequence Independent & Intelligent Locking: Flexible and efficient grid connection.

4. Pure Sine Wave Grid-Tie Control Technology: Zero grid pollution.

5. Automated Testing & Management: Low-barrier efficiency solution.

6. Cost Savings & Longevity: Durable components selected; System design lifespan >15 years.

Application

1. Comprehensive Electrical Performance Testing for Battery Modules, Packs & Clusters:

✓ Capacity Test

✓ Charge/Discharge Characteristic Test

✓ Charge/Discharge Efficiency Test

✓ Charge Retention & Recovery Capability Test

✓ Cycle Life Test

✓ Temperature Characteristic Test

✓ DC Internal Resistance Test

✓ Pulse Charge/Discharge Test

✓ Operational Profile Simulation Test

✓ Overcharge/Over-discharge Rate Tolerance Test

2. Electronic Load Function & DC Power Supply Aging with Energy Recovery:

● DC to AC Grid Feedback:

Efficiently converts DC power into AC fed back to the grid, reducing waste heat from traditional loads.

● Intelligent Aging Test:

Simulates equipment aging conditions while achieving low energy consumption, high-precision DC equipment life testing and energy recycling.

3. Battery Simulation Function:

● High-Precision Battery Charge/Discharge Simulation:

Accurately replicates battery charge/discharge curves, supports dynamic profiles & fault simulation.

● High Efficiency (>96% Energy Recovery):

Reduces test energy consumption while simultaneously validating performance and safety.

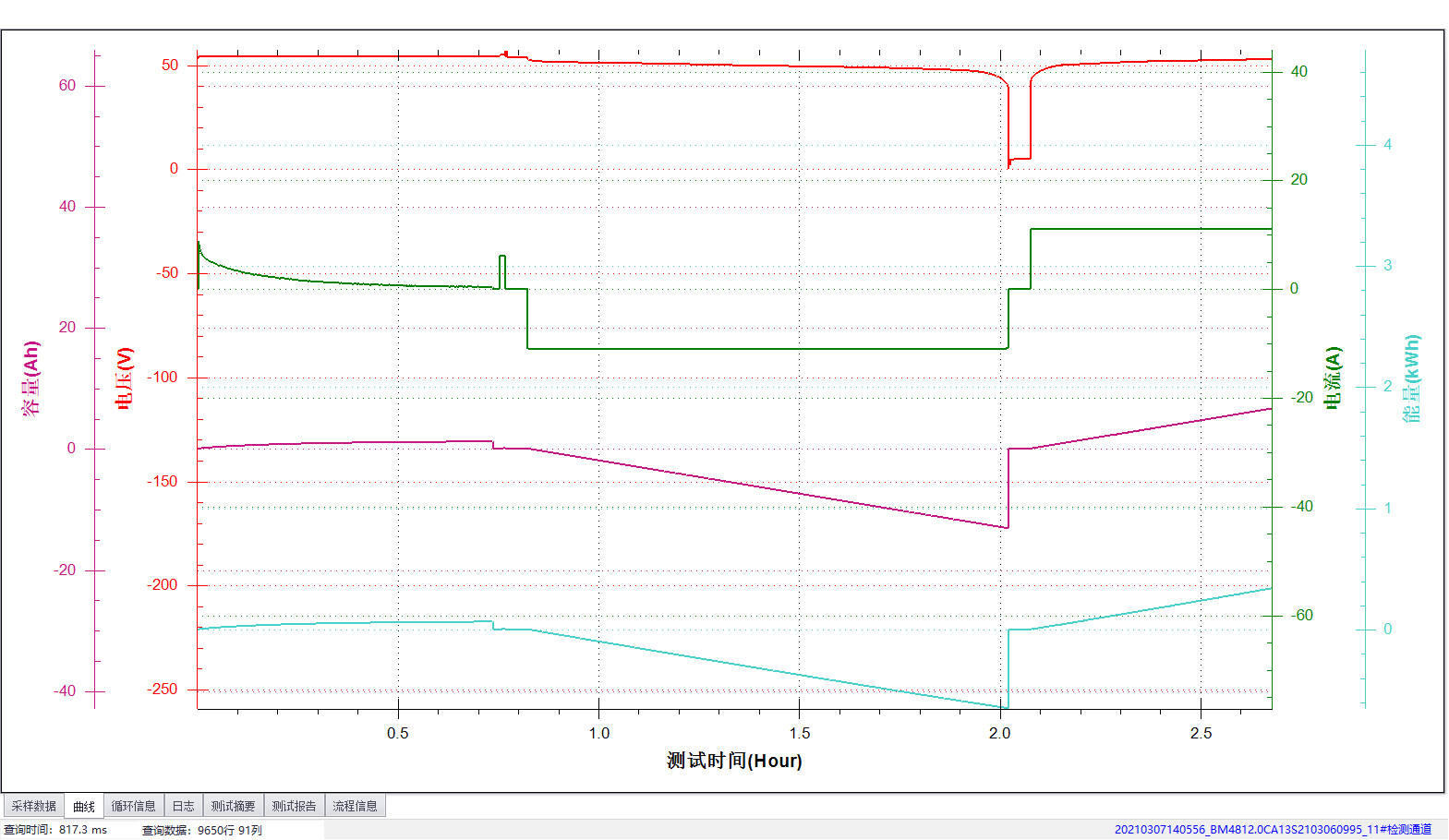

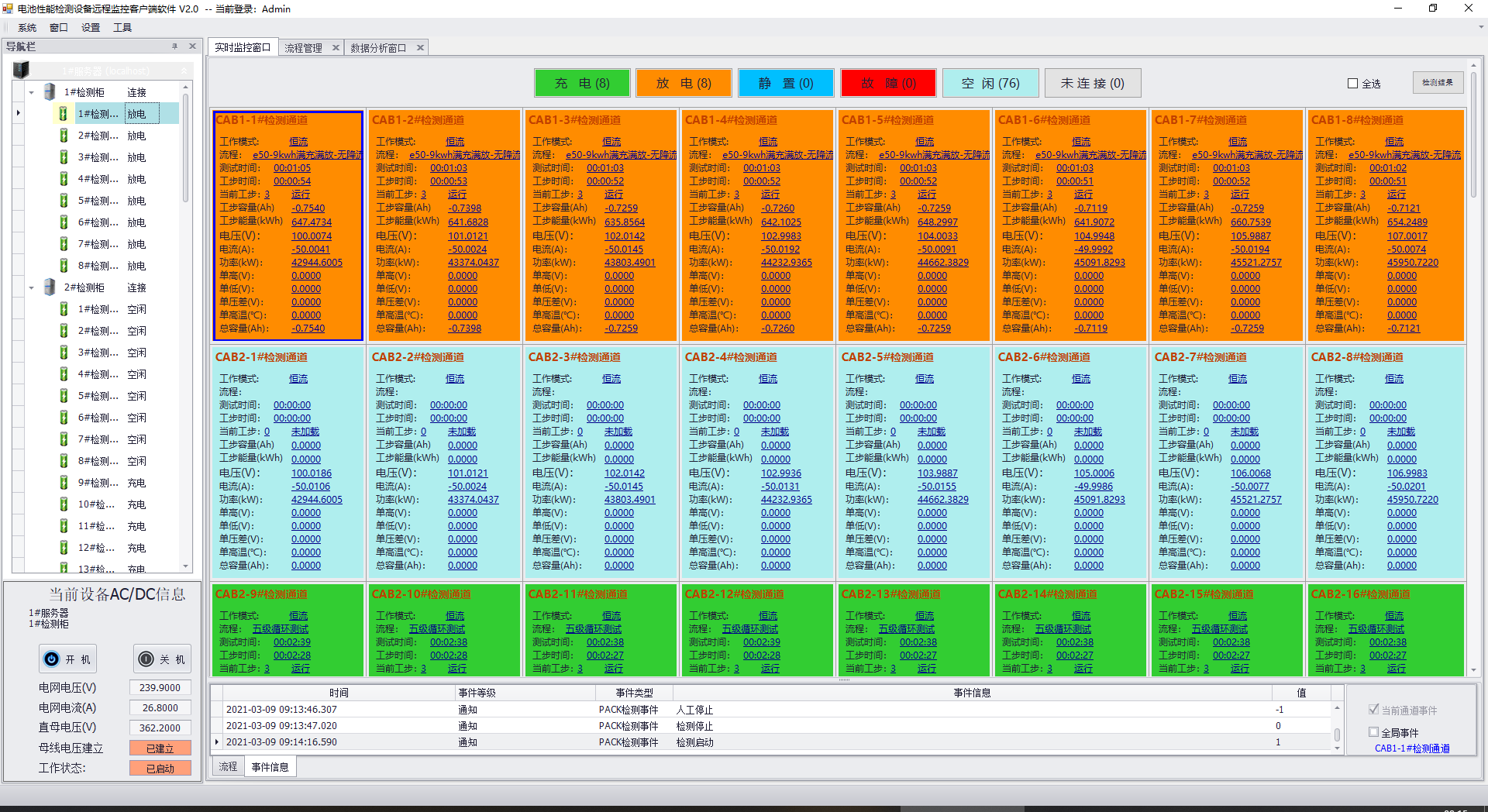

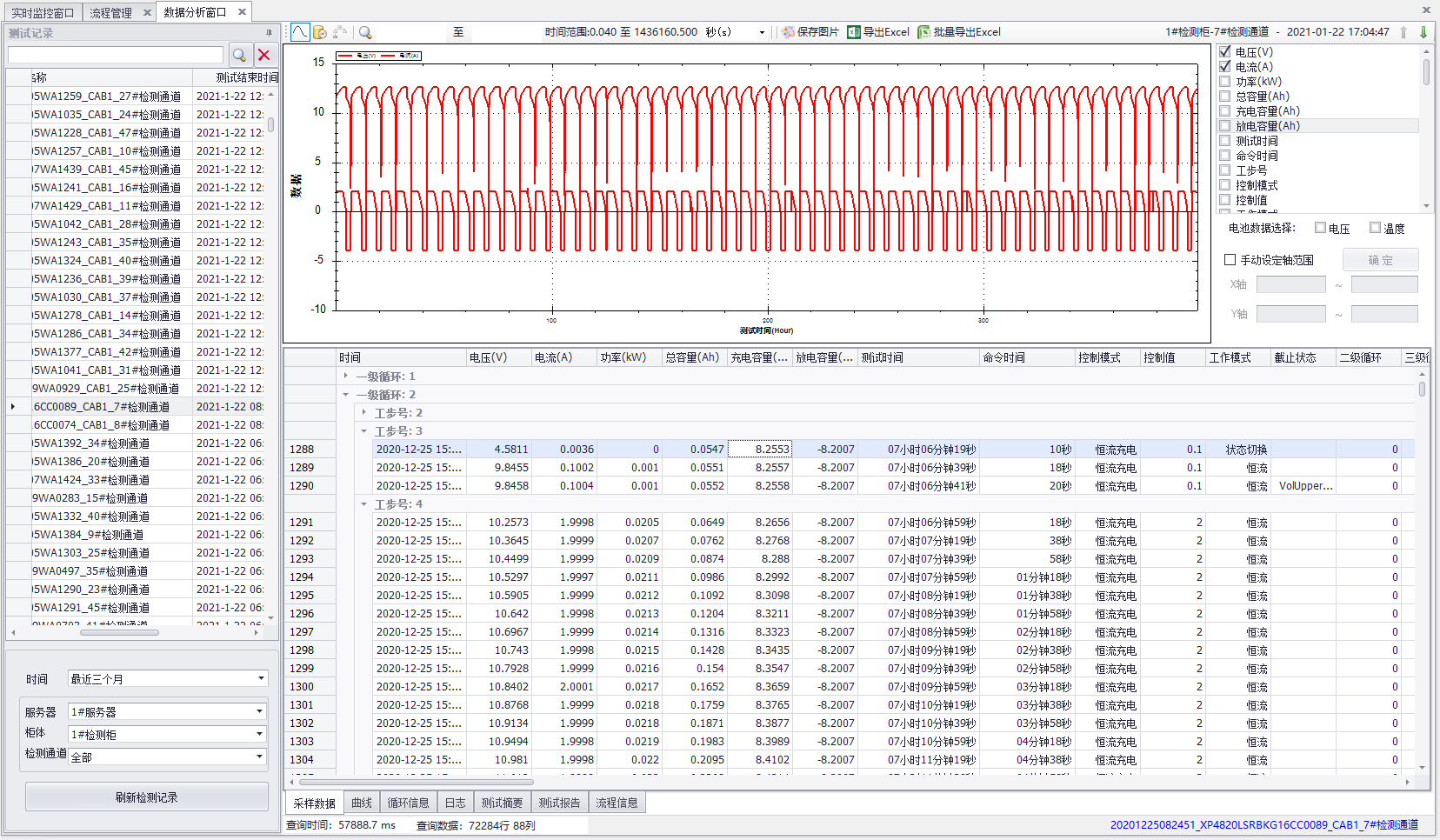

Software Interface Display (During Testing)

Specification

AC-DC (AC Side) Technical Parameters

| Parameter | Specification |

|---|---|

| Rated Voltage (V) | 380 ±10% |

| Frequency (Hz) | 50 ±2 (Other frequencies customizable) |

| Power Factor (PF) | ≥ 0.99 |

| Current Harmonic Distortion (THDi) | < 5% (at >50% load) |

| AC Input | 3P5W (3-phase 5-wire, Ground resistance ≤5Ω) |

| AC Protection | Undervoltage, Overvoltage, Overcurrent, Phase Loss, Overload, Frequency Anomaly, Overtemperature, Communication Timeout, Anti-islanding. |

DC-DC (DC Side) Technical Parameters

| Parameter | Specification |

|---|---|

| Model | SDCBUS-2400/100-500-1CD |

| DC Output Channels per Cabinet | 1 |

| Rated Power per Channel (kW) | 1200 |

| Total DC Output Power per Cabinet (kW) | 1200 |

| Charge/Discharge Voltage Range (V) | 100 - 2400 |

| Current Range per Channel (A) | ±500 |

| Parallel Current Range (Multiple Cabinets) | Parallel operation with same model cabinets |

| Energy Recovery Efficiency | ≥ 96% (at full load) |

| Output Voltage Sampling Resolution (mV) | 0.1 |

| Voltage Accuracy per Channel | ±0.05% F.S. |

| Current Accuracy per Channel | ±0.05% F.S. |

| Output Current Sampling Resolution (mA) | 1 |

| Continuous Sampling Speed (ms) | ≤ 10 |

| Current Rise/Fall Time (ms) | ≤ 5 (10% to 90% of Imax), shockless |

| Charge/Discharge Transition Time (ms) | ≤ 10 (-90% to 90% of Imax), shockless |

| Power Resolution (W) | 0.1 |

Note: Customization is supported.