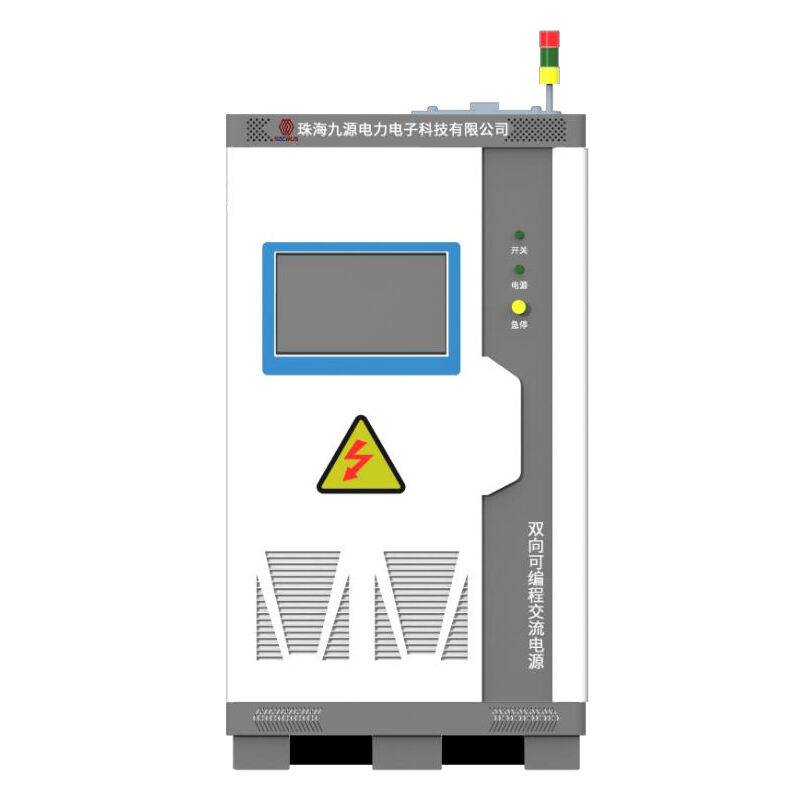

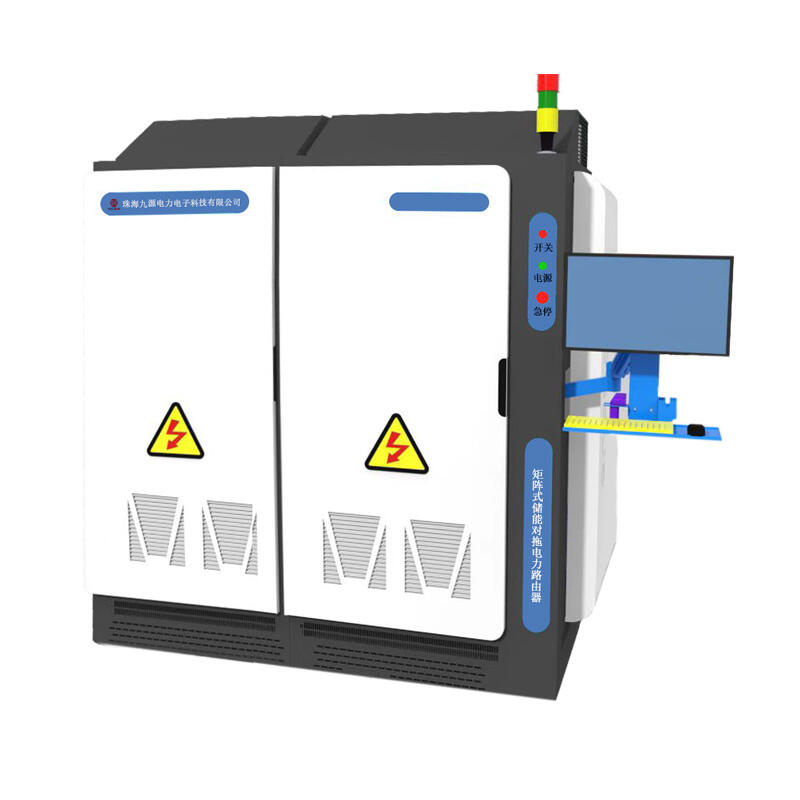

JHL Series Bidirectional Programmable AC Power Supply (BPAC)

Bidirectional programmable AC power supply is an advanced power electronic equipment integrating bidirectional energy flow, high-precision output and intelligent control. It can not only provide a stable voltage/current output as a traditional AC power source, but also feed back the power to the grid or energy storage system in an "active load" mode to achieve efficient energy recycling.

Application

![]()

- Overview

- Recommended Products

Product Features

1. Bi-directional energy flow

a) Output mode: Provide pure and stable AC power supply, support precise programmable adjustment of voltage, frequency, waveform (sine wave, square wave, harmonic, etc.).

b) Feedback mode: The power generated by the DUT (such as inverters, batteries, and energy storage systems) can be efficiently fed back to the grid or energy storage devices, with an energy saving rate of more than 90% and a significant reduction in testing costs.

2. High precision and wide range adjustment

c) Support voltage range: 0~300V/0~690V (can be customized and expanded), frequency range: 0.1Hz~1000Hz, resolution up to 0.01Hz.

d) Output accuracy: voltage/current accuracy ≤0.1%, waveform distortion (THD) <1%, meet stringent test standards.

3. Intelligent Programmable Control

e) The built-in function generator supports transient waveform generation, voltage dip/swell simulation, harmonic injection and other functions, adapting to complex test scenarios.

f) It provides multiple communication interfaces such as LAN/GPIB/USB/RS485, supports SCPI instructions, and can seamlessly integrate automated test systems.

4. Multimodal and Protection Mechanisms

g) It supports multiple working modes such as constant voltage (CV), constant current (CC), and constant power (CP), and flexibly adapts to different load requirements.

h) It has multiple protection functions such as over-voltage, over-current, short circuit, and over-temperature to ensure the safety of the equipment and the DUT.

Application

1. New energy field: grid-connected/off-grid testing of photovoltaic inverter/energy storage converter (PCS), MPPT efficiency verification.

2. Electric vehicles: Charging and discharging performance tests of on-board chargers (OBC), motor drive systems, and charging piles.

3. Industrial Automation: Dynamic Characterization of Inverters, UPS Power Supplies, and Power Electronic Devices.

4. Laboratory research and development: simulate extreme working conditions such as power grid disturbance and voltage fluctuation to verify the reliability and compatibility of equipment.

Specification

Typical equipment parameters and models

| Device Model | JHL-60F-4Q | JHL-120F-4Q | JHL-320F-4Q | JHL-630F-4Q |

| Grid-side Parameters | ||||

| Rated Power (kW) | 60 | 120 | 320 | 630 |

| Total Current Waveform Distortion Rate | ≤3% (at rated power) | |||

| Rated Grid Voltage | AC380V±15% | |||

| Rated Grid Frequency | 50Hz±5Hz | |||

| Load-side Parameters | ||||

| Rated Power (kW) | 60 | 120 | 320 | 630 |

| Total Voltage Waveform Distortion Rate | ≤1% (at rated power) | |||

| Total Current Waveform Distortion Rate | ≤2% (at rated power) | |||

| Rated Output Voltage Range | 323V~552V (Programming) | |||

| Rated Output Frequency | 45Hz~65Hz (Programming) | |||

| Equipment Shape (W*D*H/mm) | 600*600*1200 | 1000*950*1900 | 1140*950*1900 | 1840*1200*1900 |

| Equipment Weight (kg) | 400 | 600 | 1300 | 2800 |

| Highest Efficiency | 97.00% | 97.00% | 97.00% | 97.00% |

| Ingress Protection | IP21 | |||

| Operating Humidity Range | 0%~100% (no condensation) | |||

| Operating Temperature Range | -30℃~50℃ | |||

| Maximum Working Altitude | 3000m | |||

| Communication Interface | CAN/Ethernet | |||