Introduction: Beyond a Simple Power Source

When we discuss power conversion in modern technology, a specific class of devices stands out for its versatility and sophistication: the high power bidirectional power supply. Unlike traditional power supplies that only deliver energy, these advanced units act as intelligent energy exchange hubs. They can both source and sink significant amounts of power with precision, making them indispensable tools in specific, high-stakes development and validation processes. While manufacturers design these sophisticated power units, the critical task of ensuring their performance, safety, and reliability under realistic, demanding conditions falls to specialized test and measurement solutions. This is where deep expertise in high-power testing methodologies becomes paramount

Core Function: What Exactly Does It Do?

At its heart, a high power bidirectional power supply is a fully controllable, four-quadrant amplifier. In simpler terms, it can operate not only as a power source (providing current and voltage) but also as an electronic load (absorbing current and voltage). This bidirectional energy flow allows it to simulate both supply and regeneration scenarios. For instance, it can power a device under test (DUT) and then seamlessly absorb the energy that the DUT might feed back, such as during braking in an electric vehicle motor or discharge from a battery pack. This capability is crucial for creating closed-loop, realistic test environments without wasting massive amounts of energy.

Primary Application Domain: New Energy Vehicle (NEV) and Battery Ecosystem

The most prominent and demanding application driving the need for high power bidirectional power supply testing is the New Energy Vehicle sector and its associated infrastructure.

- Electric Vehicle Powertrain and Component Testing: Traction inverters, drive motors, and onboard chargers (OBC) are all bidirectional by nature. They convert battery DC to motor AC and vice versa during regenerative braking. Comprehensive testing requires a test system that can simulate the battery (source mode) and absorb regenerated power (sink mode) while performing precise, high-speed measurements of efficiency, dynamic response, and durability. A robust test platform validates that these components meet stringent automotive standards for performance and safety.

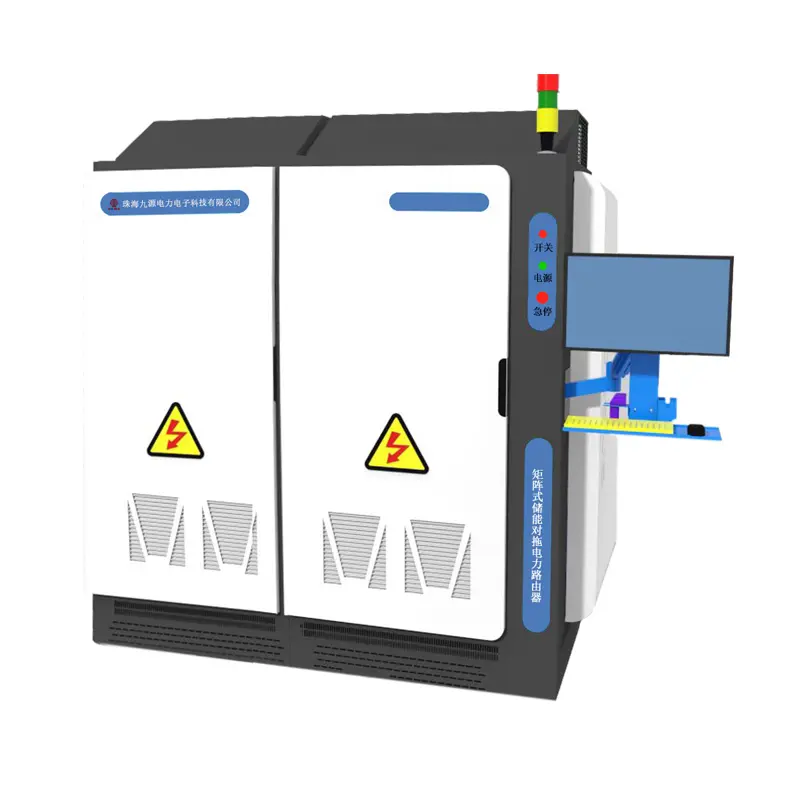

- Energy Storage System (ESS) and Stationary Battery Testing: Large-scale battery banks for grid storage or backup must be tested for both charge acceptance and discharge capability under various profiles. A test system capable of bidirectional power flow is essential for cycle life testing, emulating real-world grid interactions (like frequency regulation), and evaluating the efficiency of the complete power conversion chain (PCS - Power Conversion System). The accuracy and stability of the test equipment directly correlate to the validated lifecycle and performance claims of the ESS.

Expanding Frontiers: Advanced Research and Grid-Edge Technologies

Beyond mainstream EV and ESS, the applications are expanding into cutting-edge research and development areas.

- Microgrid and Distributed Energy Resource (DER) Simulation: Researchers developing control algorithms for microgrids need to simulate various generation sources (solar, wind) and loads in a lab. A high power bidirectional power supply, integrated into a test system, can emulate these sources and sinks dynamically, allowing for the validation of grid stability and energy management software under controlled but realistic power flow conditions.

- Fuel Cell and Hydrogen Electrolyzer Testing: The hydrogen economy involves devices that either consume power to produce hydrogen (electrolyzers) or generate power from hydrogen (fuel cells). Testing these systems, especially their power electronics interfaces, requires a platform that can handle bidirectional power to simulate different operating states and efficiency mapping across their entire input/output range.

The Critical Bridge: Specialized Test Solutions for Power Electronics

Implementing tests involving high power bidirectional power supplies is not a simple task. It requires more than just the power hardware. It demands a complete, integrated test solution engineered for accuracy, safety, and data integrity. Key challenges include:

- Precision Measurement at High Power: Accurately measuring voltage, current, and power with high bandwidth at hundreds of kilowatts or megawatts is a specialized discipline. It requires calibrated measurement subsystems immune to noise from high-power switching.

- Safety and Protection Sequencing: Testing high-power devices carries inherent risks. A professional test system incorporates layered hardware and software safety interlocks, advanced protection circuits (against over-voltage, over-current, short circuits), and fail-safe sequences to protect both the valuable DUT and the test equipment.

- Dynamic Profile Simulation and Data Acquisition: Real-world conditions are not static. The test system must be able to program and execute complex, transient power profiles (e.g., automotive drive cycles, grid fault simulations) while synchronously acquiring vast amounts of performance data for analysis. This is typically achieved through dedicated, robust communication protocols like Ethernet-based standards (e.g., IEEE 488, TCP/IP), ensuring reliable and fast control.

Conclusion: Partnering with Expertise for Validation Confidence

The evolution of power electronics towards bidirectional, high-power applications represents a significant technological leap. Validating the components and systems that utilize high power bidirectional power supplies is a complex endeavor that forms the bedrock of product reliability and innovation. Success in this field depends on partnering with test experts who possess not only the technological tools but also the deep application knowledge and procedural rigor to build trust in your test results. It is through this meticulous validation process that safer, more efficient, and more reliable energy technologies are brought to market.

Table of Contents

- Introduction: Beyond a Simple Power Source

- Core Function: What Exactly Does It Do?

- Primary Application Domain: New Energy Vehicle (NEV) and Battery Ecosystem

- Expanding Frontiers: Advanced Research and Grid-Edge Technologies

- The Critical Bridge: Specialized Test Solutions for Power Electronics

- Conclusion: Partnering with Expertise for Validation Confidence