Introduction

When it comes to selecting a reliable partner for your testing and measurement needs, choosing the right programmable power supply manufacturer is crucial. Whether you're involved in research, development, or validation processes, a high-quality programmable power supply can significantly impact the accuracy and efficiency of your work. In this article, we'll explore key factors to keep in mind during your selection process, ensuring you make an informed decision that aligns with your specific requirements. Remember, a well-chosen programmable power supply manufacturer can enhance your testing capabilities without the need for industrial automation or complex setups.

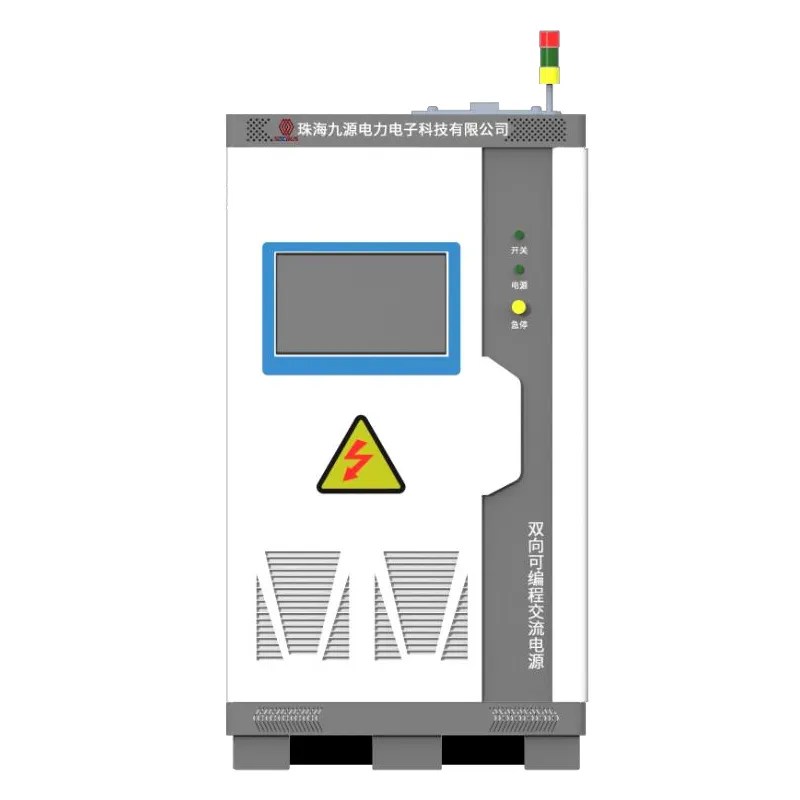

Key Performance Parameters

One of the first aspects to evaluate is the performance parameters of the programmable power supply. Look for specifications such as voltage and current ranges, stability, and accuracy. For instance, a good unit should offer precise control with minimal ripple and noise, which is essential for consistent test results in applications like battery testing or component validation. As you assess these factors, ensure the manufacturer provides detailed data sheets and validation reports to back up their claims. This step helps you avoid issues down the line and ensures compatibility with your testing environment, where reliability is paramount. By focusing on these performance metrics, you can identify a programmable power supply manufacturer that delivers the consistency needed for rigorous testing scenarios.

Communication Interface Compatibility

In today's interconnected world, communication interfaces play a vital role in integrating programmable power supplies into your test systems. Opt for manufacturers that support standard protocols like CAN, Daisy Chain, RS485, RS232, and Modbus, as these facilitate seamless data exchange and control without relying on industrial automation tools. For example, CAN and Daisy Chain setups allow for efficient multi-unit configurations, while RS485 and Modbus enable robust communication in lab environments. Avoid options that emphasize USB or other consumer-grade interfaces, as they might not offer the reliability required for professional testing. By prioritizing compatible communication interfaces, you can build a flexible and scalable test setup that meets your evolving needs.

Reliability and Durability

Durability is a critical factor when investing in a programmable power supply, as it ensures long-term performance and reduces downtime. Check for features like robust construction, thermal management, and protection mechanisms against overvoltage or short circuits. A reputable programmable power supply manufacturer will often provide information on mean time between failures (MTBF) and environmental testing results, giving you confidence in the product's lifespan. In testing applications, where equipment is frequently used in varied conditions, this reliability translates to consistent outcomes and lower maintenance costs. Always review user feedback and industry certifications to gauge the manufacturer's commitment to quality.

Technical Support and Service

Even the best equipment can encounter issues, so reliable technical support is essential. Choose a manufacturer that offers comprehensive services, including detailed documentation, responsive customer support, and readily available spare parts. For instance, look for companies that provide online resources, training modules, and direct assistance to help you troubleshoot problems quickly. This is particularly important in testing environments, where delays can impact project timelines. A supportive programmable power supply manufacturer will also offer firmware updates and customization advice, ensuring your setup remains up-to-date and efficient over time.

Customization Options

Every testing scenario has unique demands, so flexibility in customization can be a game-changer. Seek out manufacturers that allow for tailored solutions, such as adjustable parameters, software integrations, or modular designs. This might include the ability to program specific test sequences or adapt communication protocols like Modbus for your lab's needs. By opting for a programmable power supply manufacturer that emphasizes customization, you can optimize your testing processes without compromising on performance. This approach not only saves time but also enhances the overall value of your investment.

Cost Considerations

While budget is always a factor, it's important to balance cost with long-term value. Avoid the temptation to choose the cheapest option, as it might lead to higher expenses from repairs or inefficiencies. Instead, compare the total cost of ownership, including energy consumption, maintenance, and potential upgrades. A reliable programmable power supply manufacturer will offer transparent pricing and value-added features that justify the investment. For testing applications, this means selecting a unit that delivers consistent performance without unnecessary frills, ensuring you get the best return on your spending.

Safety Features

Safety should never be overlooked, especially in environments where testing involves high voltages or currents. Look for programmable power supplies with built-in protections like overload cutoffs, isolation mechanisms, and compliance with international safety standards. These features minimize risks to both equipment and personnel, making your operations smoother and more secure. A trustworthy programmable power supply manufacturer will highlight these aspects in their product descriptions and provide guidance on safe usage practices. By prioritizing safety, you can focus on your core testing tasks with peace of mind.

Software and Integration

The software that accompanies a programmable power supply can greatly influence its usability. Opt for manufacturers that offer intuitive control software, API access, and compatibility with common lab platforms. This allows for easy automation of test sequences and data logging, without requiring advanced programming skills. For example, integration with protocols like Modbus or Daisy Chain can streamline multi-device setups in research labs. A forward-thinking programmable power supply manufacturer will ensure their software is regularly updated and user-friendly, enhancing your overall testing experience.

Conclusion

Selecting the right programmable power supply manufacturer involves a careful balance of performance, compatibility, reliability, and support. By considering factors like communication interfaces, customization, and safety, you can find a solution that fits your testing needs without venturing into industrial automation. Remember, a well-informed choice not only improves your current operations but also sets the stage for future growth. If you're looking for expert guidance in this area, feel free to explore more resources to make the best decision for your requirements.