Flexible Output Adjustment Meets Diverse Needs

A programmable DC power supply stands out for its excellent flexibility in output adjustment. Unlike traditional fixed-output power supplies that can only provide a single or limited range of voltage and current values, this type of power supply allows users to precisely set and adjust output parameters according to specific application requirements. For example, in the R&D process of electronic components, engineers may need to test the performance of components under different voltage conditions. With a programmable DC power supply, they can easily program and modify the output voltage within a wide range, without the trouble of replacing multiple fixed power supplies. This flexibility not only saves time and effort but also greatly improves the efficiency of R&D and testing work. Whether it is for small - scale laboratory experiments or large - scale industrial production testing, the programmable DC power supply can flexibly adapt to various scenarios, meeting the diverse needs of different users.

High Precision Ensures Reliable Test Results

High precision is another significant advantage of a programmable DC power supply. In many fields, such as electronic product testing and scientific research, the accuracy of power supply output directly affects the reliability and validity of test results. A high - quality programmable DC power supply can achieve extremely high output precision in terms of voltage and current. It can control the output error within a very small range, ensuring that the power parameters provided to the tested equipment are stable and accurate. For instance, when testing the stability of a precision sensor, even a tiny fluctuation in the power supply voltage may lead to large deviations in the sensor's test data. However, with a programmable DC power supply, the output voltage can be maintained at a stable and accurate value, effectively avoiding such problems. This high - precision performance makes the programmable DC power supply an indispensable tool in fields that require strict control of power parameters, providing a solid guarantee for obtaining reliable test results.

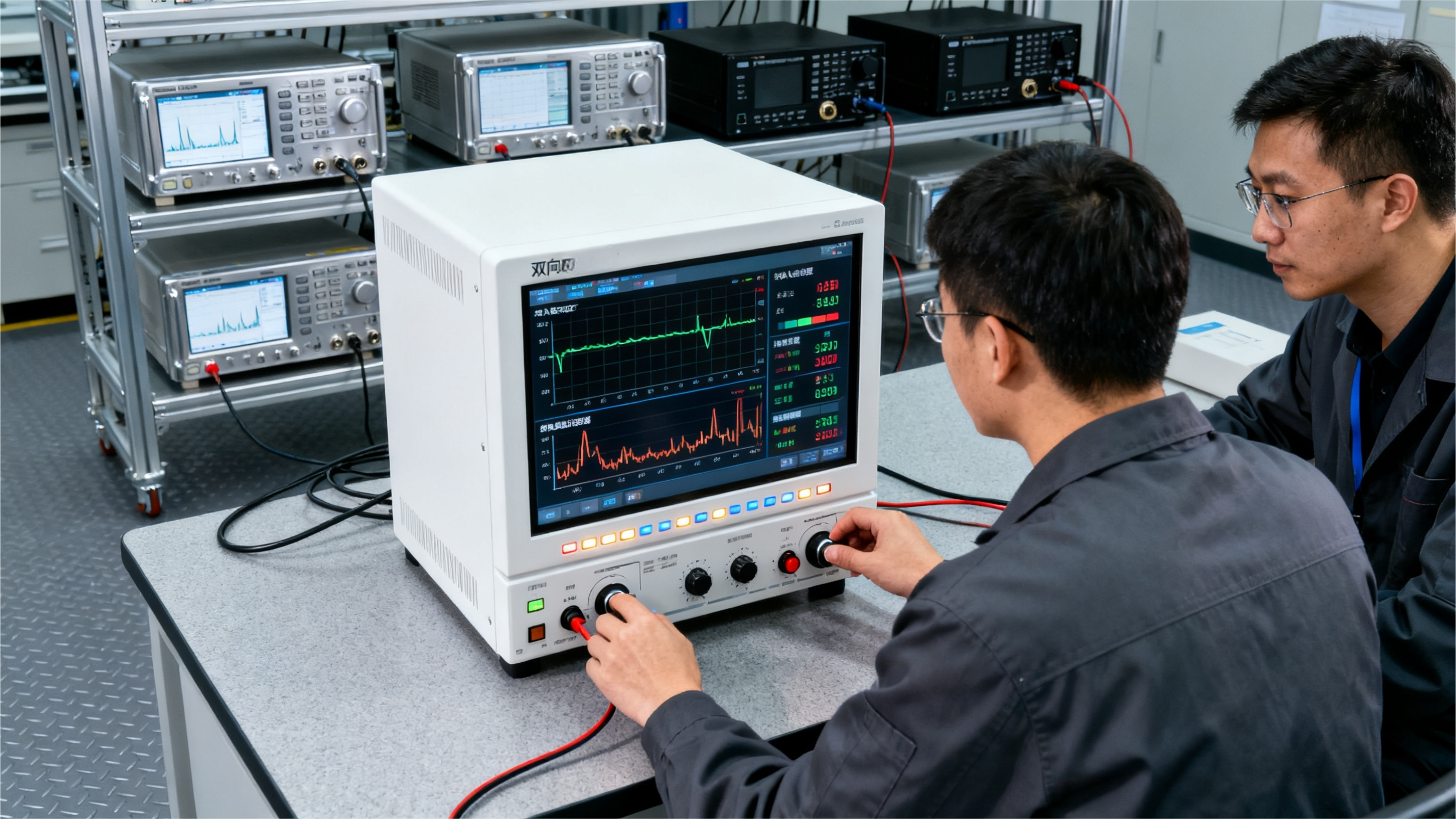

Intelligent Control Simplifies Operation Processes

Intelligent control is a key feature that makes the programmable DC power supply more user - friendly. Modern programmable DC power supplies are usually equipped with a variety of intelligent control functions and interfaces, which greatly simplify the operation process. They support multiple communication interfaces, such as such as Daisy Chain, RS485 with Modbus protocol, RS232, and CAN, enabling seamless connection with computers, controllers, and other equipment. Users can remotely control the power supply through dedicated software or programming commands, realizing automated operation. For example, in an automated production line, the programmable DC power supply can be integrated into the overall control system. The system can automatically send control commands to the power supply according to the production process, adjusting the output parameters in real - time to meet the needs of different production steps. This not only reduces the manual operation intensity but also avoids errors caused by human factors. Additionally, some programmable DC power supplies also have built - in intelligent protection functions. They can automatically detect abnormal conditions such as overvoltage, overcurrent, and overtemperature, and quickly take protective measures, such as cutting off the output, to ensure the safety of the power supply and the tested equipment. This intelligent protection mechanism further enhances the reliability and safety of the power supply during use.

Energy - Saving and Environmental Protection Conforms to Development Trends

In today's society, energy conservation and environmental protection have become important development trends. The programmable DC power supply also has certain advantages in this aspect. Compared with some traditional power supplies, it adopts advanced power conversion technologies and circuit designs, which can effectively improve energy conversion efficiency. Higher energy efficiency means that less electrical energy is wasted during the power supply process, reducing energy consumption and operating costs. For example, in long - term continuous operation scenarios, such as data centers and industrial production lines, the energy - saving effect of the programmable DC power supply will be more obvious. A small increase in energy efficiency can save a large amount of electricity costs over time. Moreover, some programmable DC power supplies also have energy - recovery functions. In specific application scenarios, such as battery testing, when the battery is discharged, the power supply can recover the electrical energy released by the battery and feed it back to the power grid or store it for reuse. This not only further saves energy but also reduces the impact on the environment. By using a programmable DC power supply, enterprises and research institutions can not only improve work efficiency but also contribute to energy conservation and environmental protection, in line with the social development concept of sustainable development.

Conclusion

In summary, the programmable DC power supply excels in power equipment with four complementary core advantages, effectively meeting diverse scenario needs. Its flexible output adjustment breaks the limits of traditional fixed power supplies, adapting to both lab experiments and industrial testing to boost R&D and testing efficiency. Its high precision ensures stable, accurate output, providing a critical guarantee for reliable results in fields requiring strict power parameter control. Its intelligent control simplifies operations, via multi-interface connectivity and remote automation, it cuts manual work and errors, while built-in protection enhances safety and reliability. Additionally, its energy-saving features (backed by advanced conversion tech and optional energy recovery) align with sustainable development, helping reduce costs and protect the environment.

Together, these advantages make it a core tool in R&D, testing, and production. It solves traditional power supply pain points (inflexible output, unstable precision, cumbersome operation) and responds to industry demands for efficiency, reliability, and sustainability, strongly supporting high-quality development in related sectors.